Quality Policy

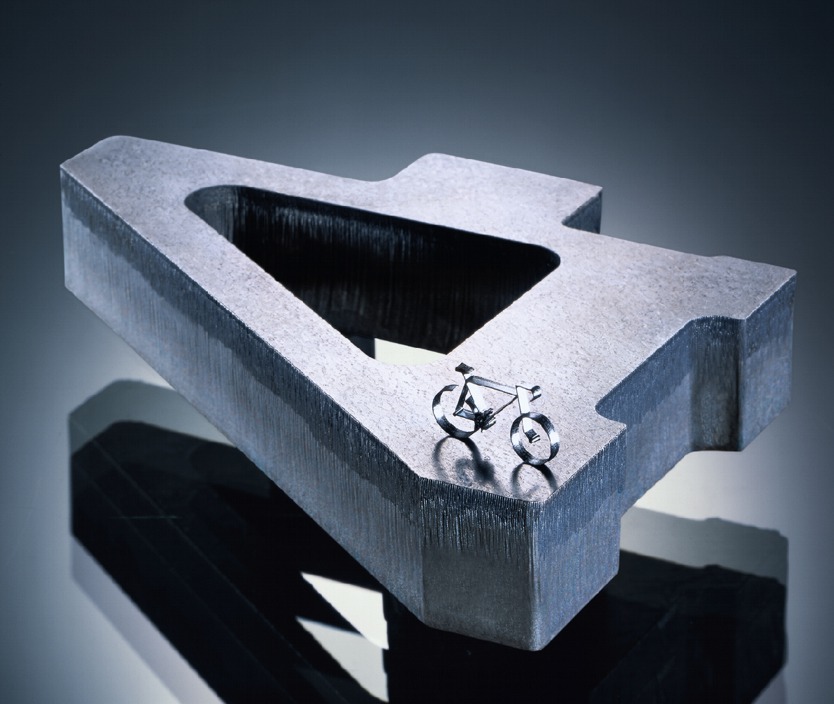

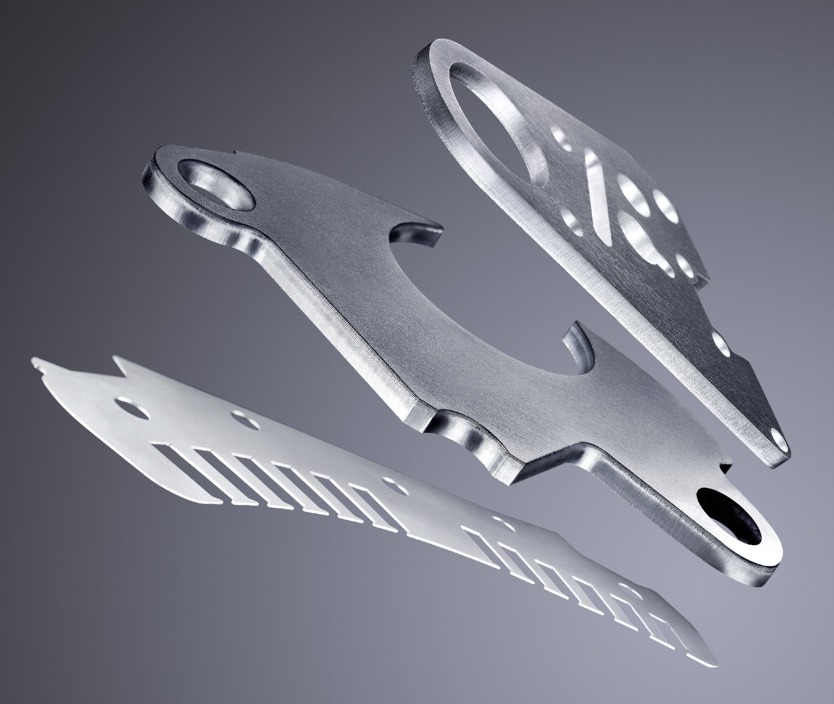

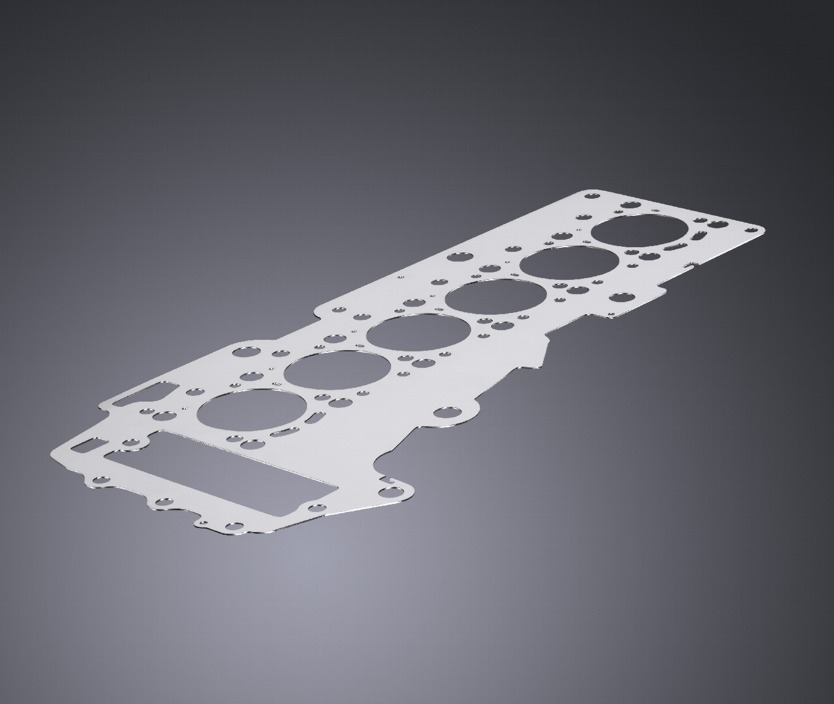

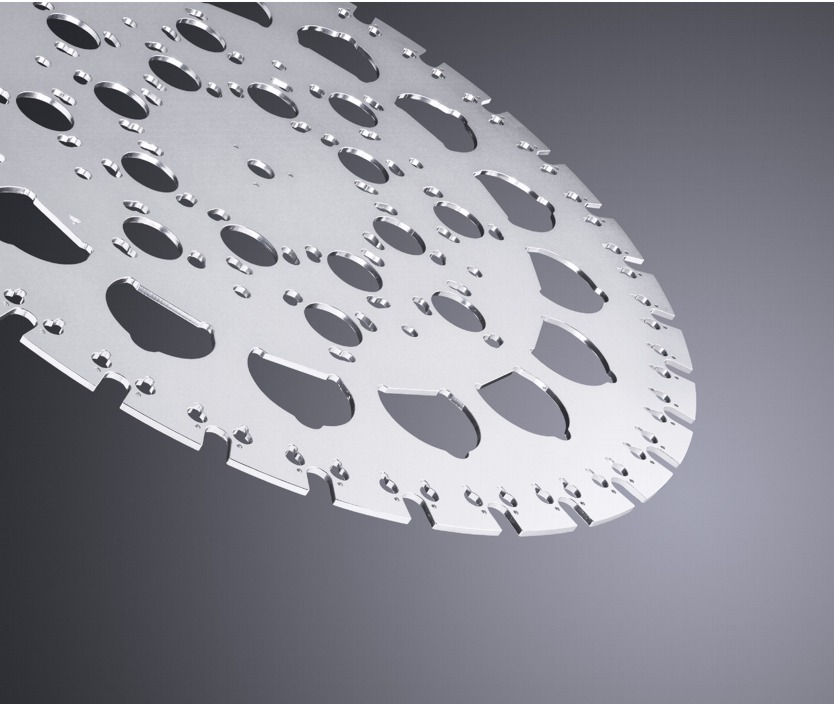

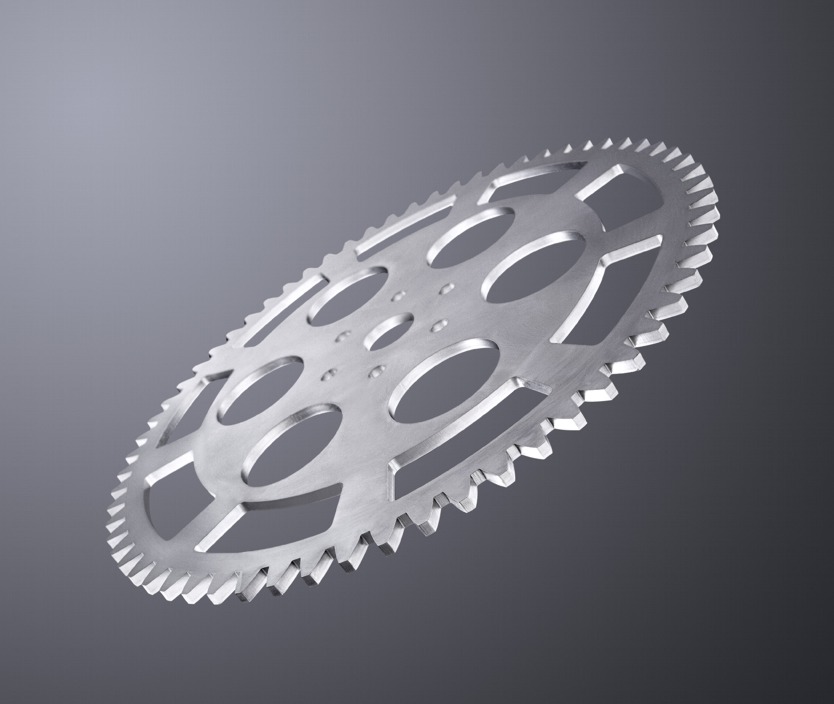

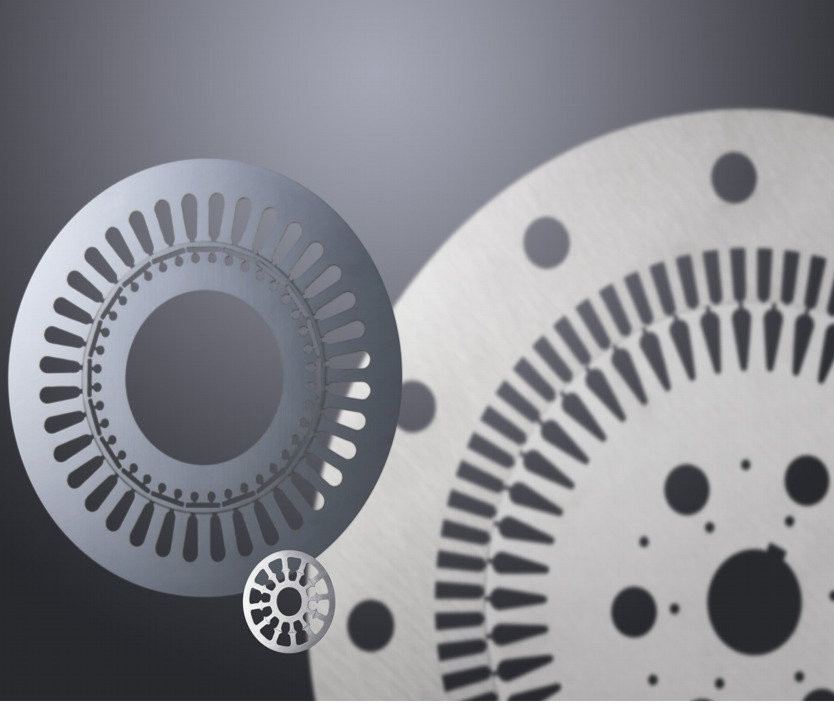

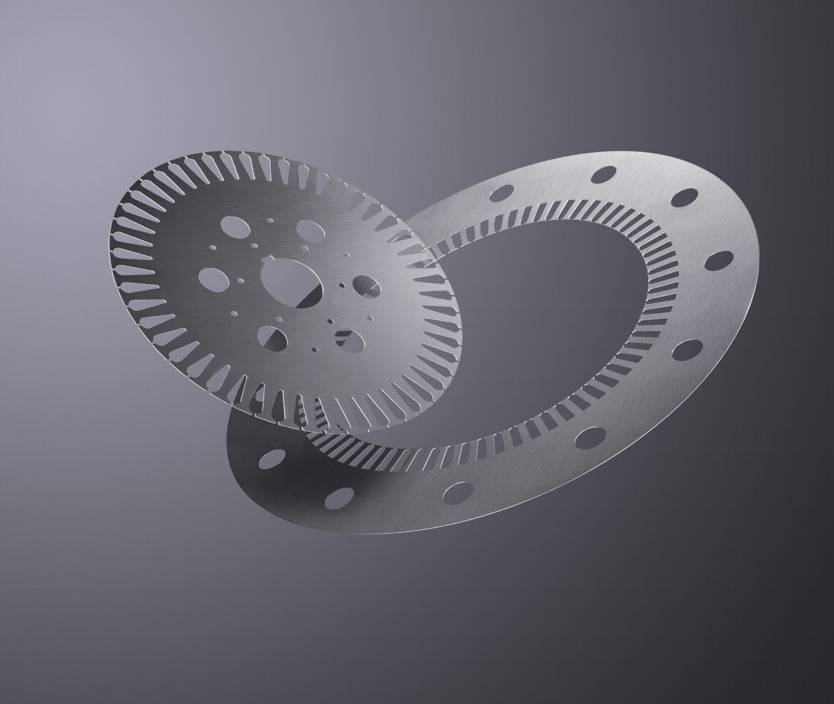

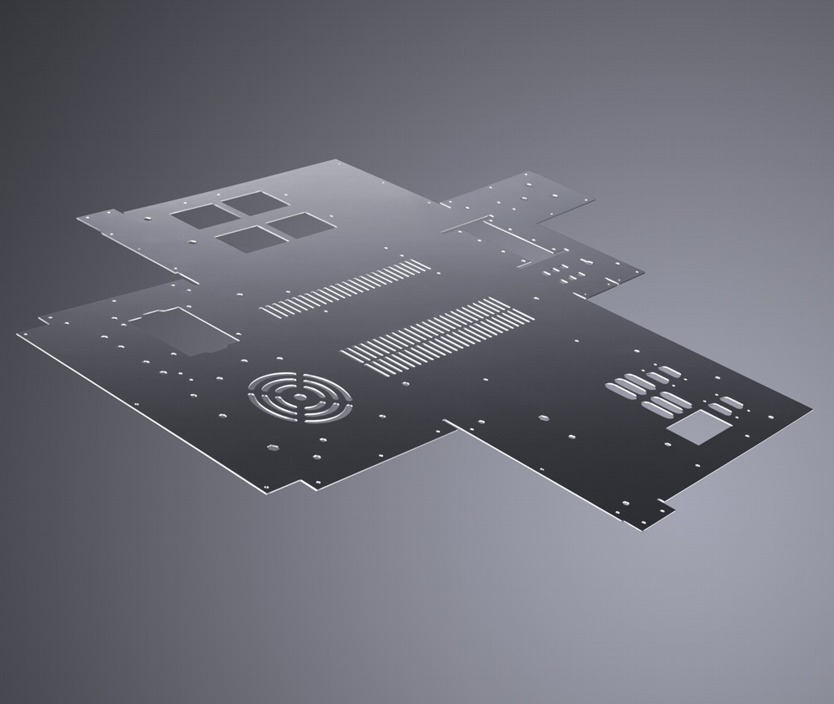

Laser Cutting Machine works on the principle by heating the material by the focused laser beam above its melting point.The resulting molten material is ejected either by a coaxial gas jet or the induced vapor pressure.Laser cutting is applied for different kinds of materials like Stainless Steel, Mild Steel, and Aluminum etc. where it require precise, fast and force-free processing. Laser creates narrow kerfs and thus achieve high-precision cuts.

In simple terms, laser cutting uses a high energy infra-red laser beam to cut a wide range of materials. A focusing lens concentrates all of the energy from the laser source onto a single point on the material, causing it to melt rapidly – assist gases are then used to expel the molten material. These assist gases can include oxygen and nitrogen. The most appropriate gas is typically chosen based onthe type of the material that is being cut.It’s a popular choice for many applications due to its extremely high level of accuracy, speed,and relatively low cost.

In simple terms, laser cutting uses a high energy infra-red laser beam to cut a wide range of materials. A focusing lens concentrates all of the energy from the laser source onto a single point on the material, causing it to melt rapidly – assist gases are then used to expel the molten material. These assist gases can include oxygen and nitrogen. The most appropriate gas is typically chosen based onthe type of the material that is being cut.It’s a popular choice for many applications due to its extremely high level of accuracy, speed,and relatively low cost.

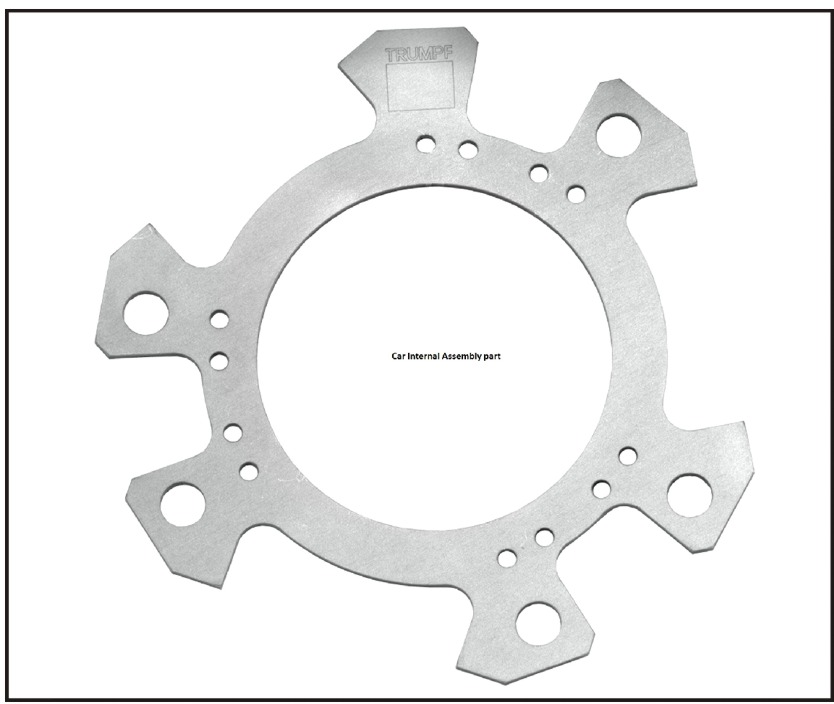

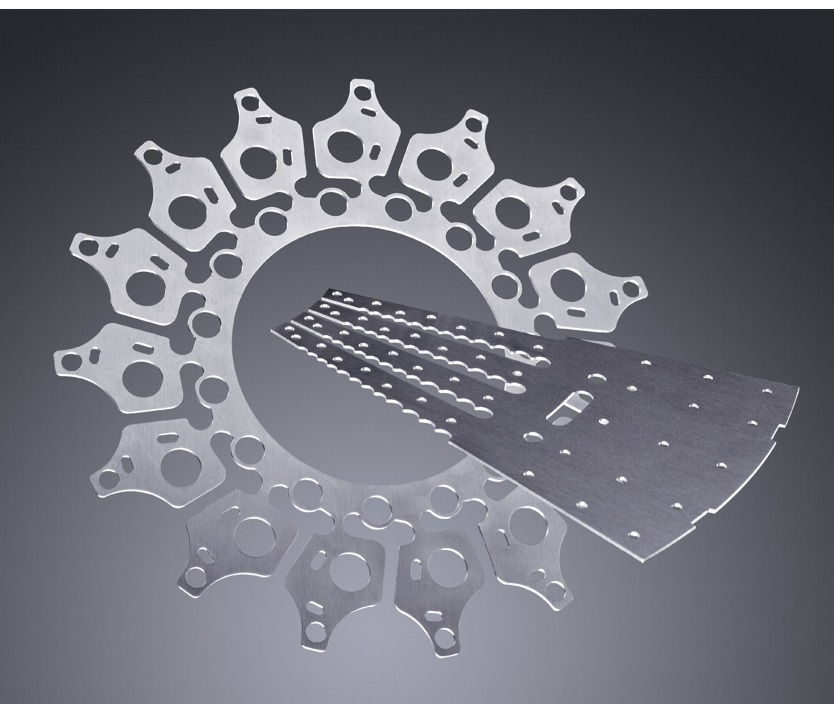

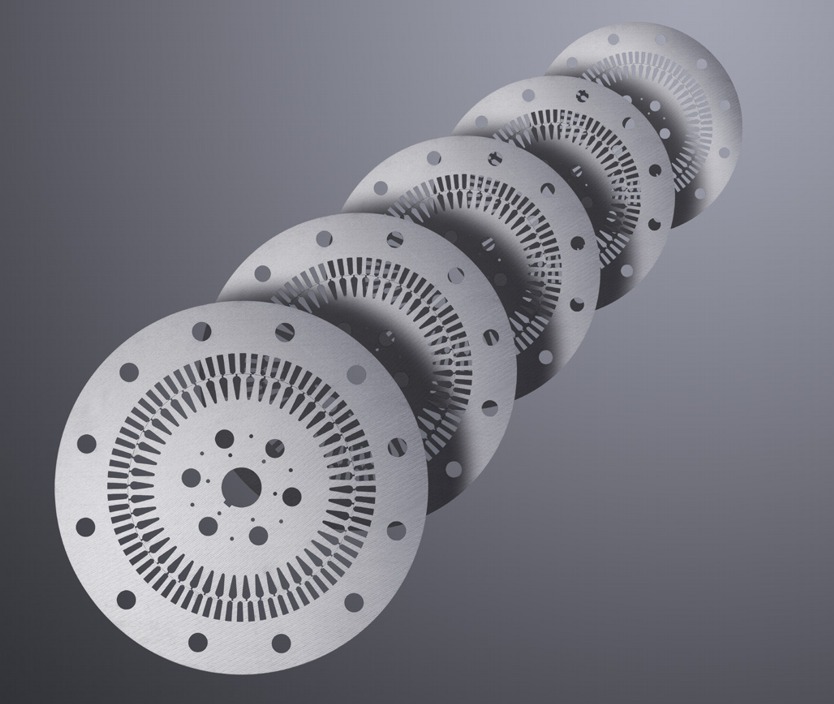

We LASER CUT Below Materials :

* Mild Steel

* Stainless Steel

* Aluminiu

*Copper & Brass

*Titanium